MTS Tumbler screening machines

Modular design for easy handling

- Model sizes: 600 – 1000 – 1200 – 1600 –2000 – 2400 and 2600 mm in diameter, with up to 5 decks

- Specifications: mild steel, stainless steel or finishing on choice

- Circular construction with central material feed, variable outlet positions and easy to clean

- Automatic centring of the screens

- Food-safe U-shaped silicon gaskets enable easy fitting

- Patented adjustment system allows the operating parameters to be set quickly and simply

- Screening motion independent of throughput

- No oversize grains in the fine material

- Fragile materials and agglomerates are not destroyed

- Particularly suitable for very lightdense materials

- Machines are shipped ready for operation and preset for the relevant product – in 90 per cent of all cases no further adjustment is necessary

- Low height and modest power requirements

- Compatible with other tumbler screen machines

- MINOX-patented Pneumatic lifting system for fast and save screen exchange

- MINOX-patented baloncing system for low dynamic loads on foundation

| Model | MTS 600 |

MTS 1000 |

MTS 1200 |

MTS 1600 |

MTS 2000 |

MTS 2400 |

MTS 2600 |

|---|---|---|---|---|---|---|---|

| Diameter (mm) | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Screen area /deck (m²) | 0,29 | 0,71 | 1,1 | 1,83 | 2,62 | 3,63 | 5,31 |

| Space required (m²) | 0,4 | 1,2 | 1,6 | 2,5 | 3,6 | 5,2 | 6,8 |

| Max. screen decks | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Connected load (kW) | 0,25 | 1,5 | 2,2 | 4 | 4 | 5,5 | 5,5 |

| Screen cleaning systems | |||||||

| Balls | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks |

| Brushes | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks |

| Air jet | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks |

| Air jet + brushes | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks | 2 Decks |

| Ultrasound | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks | 5 Decks |

| Sieve attachment | 2 Decks | 2 Decks | 2 Decks | 1 Deck | 1 Deck | 1 Deck | 1 Deck |

| Base plate (edge length) | 630 | 930 | 1100 | 1340 | 1340 | 1740 | 1940 |

| Height (mm) | 850 | 1155 | 1480 | 1480 | 1500 | 1470 | 1580 |

| 1 deck weight (kg) | 140 | 490 | 700 | 980 | 1050 | 1690 | 1900 |

| Height (mm) | 965 | 1280 | 1640 | 1640 | 1660 | 1590 | 1710 |

| 2 decks weight (kg) | 155 | 535 | 770 | 1060 | 1140 | 1780 | 2000 |

| Height (mm) | 1080 | 1400 | 1800 | 1800 | 1820 | 1710 | 1840 |

| 3 decks weight(kg) | 170 | 580 | 840 | 1140 | 1230 | 1870 | 2100 |

| Height (mm) | 1200 | 1525 | 1960 | 1960 | 1980 | 1830 | 1970 |

| 4 decks weight(kg) | 185 | 625 | 910 | 1220 | 1320 | 1960 | 2200 |

| Height (mm) | 1310 | 1650 | 2120 | 2120 | 2140 | 1950 | 2100 |

| 5 decks weight(kg) | 200 | 670 | 980 | 1300 | 1410 | 2050 | 2300 |

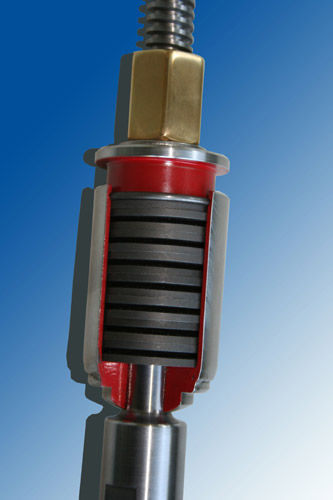

POWER SPRINGS

MINOX Siebtechnik GmbH developed the Power Springs to reduce maintenance costs and significantly raise safety standards.

MINOX Siebtechnik GmbH developed the Power Springs to reduce maintenance costs and significantly raise safety standards.

The dimensions of the gaskets can be negatively affected by the temperature of the materials, so that after a certain time the tensioning screws need to be manually tightened, especially on multi-deck machines. These springs automatically take care of the job.

The Power Springs consist of a case with set of springs fitted inside. The trapezoidal thread with a 4mm pitch, combined with a brass nut at the upper end guarantee outstanding mechanical durability and rapid fitting.

A colour code on the safety tensioning nut enables a simple sight test without turning the machine off. This makes it easy to check if the screw is providing sufficient tension.

A tumbler screening machine fully equipped with Power Springs and lifting device achieves the highest safety standards and the best material efficiency.

Original – Minox pneumatic lifting device for tumbler screening machines (trademark protected)

MINOX Siebtechnik GmbH invests continually in developing its tumbler screening machines to improve their functionality and handling. This has always been one of the company’s primary objectives.

MINOX Siebtechnik GmbH invests continually in developing its tumbler screening machines to improve their functionality and handling. This has always been one of the company’s primary objectives.

The MINOX machines in the MTS series are extremely robust and have long been equipped with genuine automatic screen centring.

The lateral flange this requires makes it easier to use a U-shaped gasket, which is simply passed over the screens. This means it is no longer necessary to go through the complicated process of gluing the flat gaskets used previously.

Nevertheless, until now a screen change could only be completed by manually removing the cover and the intermediate rings or by using a chain hoist or crane attached to the lifting rings on the screen casing. Despite the centred screen this makes changing the screen quite an arduous task, especially on large machines with 4-5 decks.

The latest invention from MINOX is a pneumatic lifting device enabling the intermediate rings and cover to be raised and lowered individually. Now the screen coverings can be exchanged quickly and easily or even just inspected.

Depending on the size of the machine and the number of screen decks, a 2 to 4 point lifting device is used. It is permanently attached to the tumbler screening machine and is ready to be connected to the air compressor, with pneumatic control for raising and lowering. As the lifting device is permanently attached it can be used at any time.

The pneumatic lifting device from MINOX can be retrofitted to almost all tumbler screening machines.

Effective screen cleaning guarantees uninterrupted operations

Particularly when screening fine particles the mesh can often become clogged by grains and dust or electrostatically charged. This can reduce performance and screening quality, sometimes considerably. In order to ensure uninterrupted operations the screen therefore needs to be cleaned in an appropriate way for the product. Due to their circular construction and three-way motion, tumbler screening machines are particularly suitable for rapid and easy fitting with the various screen cleaning systems.Air jet cleaning

A fan blows air or gas into the central cavity and then into the jet arms. The powerful air jet reaches speeds of up to 120m/s at the nozzle and cleans the screen mesh from below. A kind of fluid bed is created at the point where the jet stream rotates which causes the product to separate. At the same time the air is extracted, either at the fine grain outlet or via an extraction nozzle in the bottom pan. The air flows back across the screen and draws the fine material through the mesh, supplementing the mechanical screening effect. This technology is mostly used for products which are especially difficult to screen, or are sticky, fatty, greasy or electrostatically charged, e.g. spices, milk powders, metal powders etc.

A fan blows air or gas into the central cavity and then into the jet arms. The powerful air jet reaches speeds of up to 120m/s at the nozzle and cleans the screen mesh from below. A kind of fluid bed is created at the point where the jet stream rotates which causes the product to separate. At the same time the air is extracted, either at the fine grain outlet or via an extraction nozzle in the bottom pan. The air flows back across the screen and draws the fine material through the mesh, supplementing the mechanical screening effect. This technology is mostly used for products which are especially difficult to screen, or are sticky, fatty, greasy or electrostatically charged, e.g. spices, milk powders, metal powders etc.

Air jet and brush cleaning

For many difficult products such as plastic powders a brush is also required in addition to the air jet in order to clear the screen mesh of clogged particles.

For many difficult products such as plastic powders a brush is also required in addition to the air jet in order to clear the screen mesh of clogged particles.

Brush cleaning

This method is particularly mild and the action of the conical roller brushes under the screen is especially suitable for round, crystalline and fragile materials. The brushes are driven by a reduction gear fitted to the shaft in the bottom pan.

This method is particularly mild and the action of the conical roller brushes under the screen is especially suitable for round, crystalline and fragile materials. The brushes are driven by a reduction gear fitted to the shaft in the bottom pan.

Bouncing ball cleaning

Special long-lasting, food safe rubber balls are bounced against the bottom of the screen mesh from a perforated plate below and dislodge the clogged particles. It is simple to handle and service and can be used with most granular products.

Special long-lasting, food safe rubber balls are bounced against the bottom of the screen mesh from a perforated plate below and dislodge the clogged particles. It is simple to handle and service and can be used with most granular products.

Sieve attachment

Steel or rubber spatulas rotate across the screen and gently press agglomerated material, e.g. instant coffee, through the screen.

Steel or rubber spatulas rotate across the screen and gently press agglomerated material, e.g. instant coffee, through the screen.